100% Original Factory Back Plate - Rubber Lined Slurry Pump SHR/250ST – Minerals

100% Original Factory Back Plate - Rubber Lined Slurry Pump SHR/250ST – Minerals Detail:

Pump Model: SHR/250ST (12/10ST-AHR)

SHR/250ST is equivalent to 12/10ST-AHR, a 10” discharge rubber lined slurry pump, which is widely used for corrosive slurry applications. SHR/250ST is horizontal centrifugal type heavy duty rubber lined slurry pump. It is used to handle tailings in various mining sectors. Plus, it can also be used to feed cyclones for sand washing plants, quarries, etc. SHR is high corrosion-resistant pump series for the hydraulic conveyance of liquids-solids of any type. It’s wet-end spare parts are made of natural rubber R55, a black soft natural rubber, which has superior erosion resistance to all other materials in fine particle slurry applications. The high erosion resistance of R55 is provided by the combination of its high resilience, high tensile strength and low Shore Hardness.

In fact, this model is a little special, because this pump is installed with metal impeller, although the inner liners are rubber. This way, the actual head of the pump will be higher than that of fully rubber lined.

Applications:

Mine Dewatering; Sand Pumping; Manure Slurry; Oil Sands; Tailings and Aggregate; Coal Production etc.

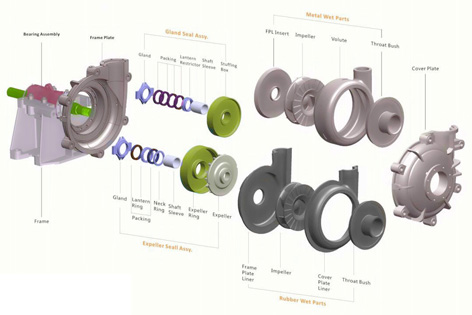

Material Construction:

| Part Description | Standard | Alternative |

| Impeller | A05 | Polyurethane, Metal A05 |

| Cover Plate Liner |

R55 | Polyurethane |

| Frame Plate Liner |

R55 | Polyurethane |

| Throatbush | R55 | Polyurethane |

| Split Outter Casings | Grey Iron | Ductile Iron |

| Shaft | Carbon Steel | SS304, SS316 |

| Shaft Sleeve | SS304 | SS316, Ceramic, Tungstan Carbide |

| Shaft Seal | Expeller Seal | Gland Packing, Mechanical Seal |

| Bearings | ZWZ, HRB | SKF, Timken, NSK etc. |

Construction & Structure:

Specifications:

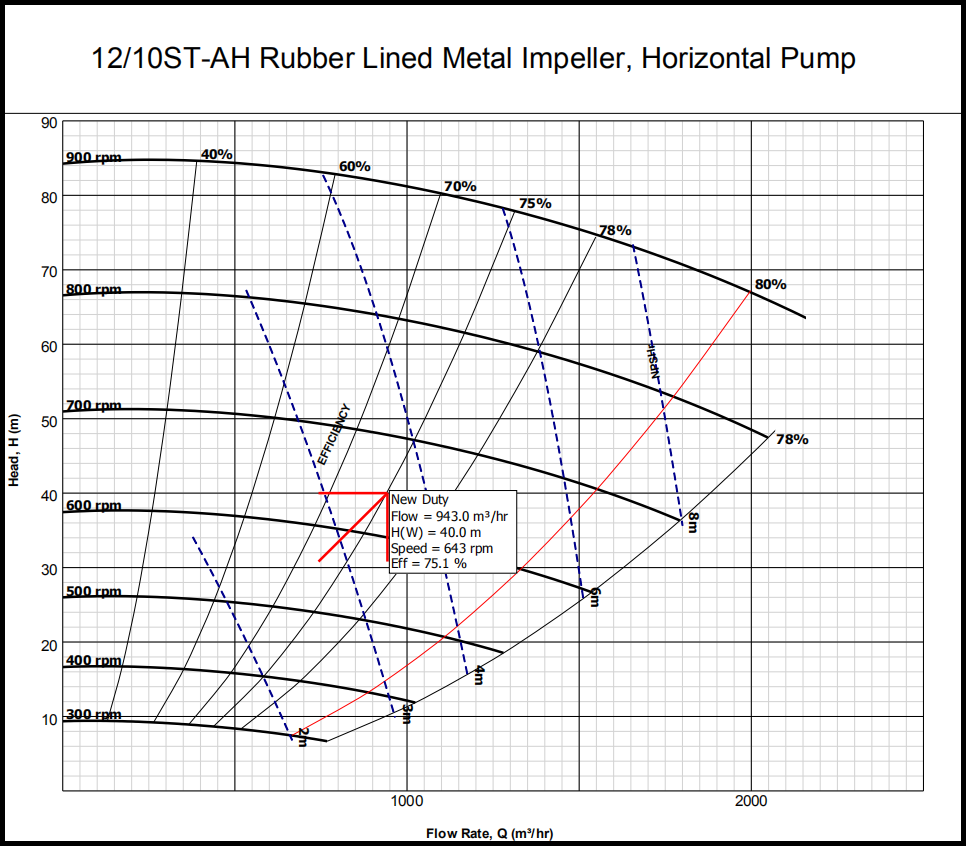

Flowrate: up to 1500m3/hr; Head: upto 50m; Speed: upto 650rpm; Bearing Assembly: SH005M

(Optional Bearing Assembly: SH005M with Max. Motor Power of 560Kw)

Impeller: 5-Vane Closed Type with Vane Diameter: 686mm; Max. Passage Size: 76mm; Max. Efficiency: 80%

Performance Curve:

Product detail pictures:

Related Product Guide:

Slurry Pump Knowledge

It is actually our accountability to satisfy your needs and effectively serve you. Your pleasure is our best reward. We're on the lookout forward for your stop by for joint growth for 100% Original Factory Back Plate - Rubber Lined Slurry Pump SHR/250ST – Minerals , The product will supply to all over the world, such as: Lithuania , Congo , Washington , We adhere to the honest, efficient, practical win-win running mission and people-oriented business philosophy. Excellent quality, reasonable price and customer satisfaction are always pursued! If you are interested in our products, just try to contact us for more details!

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.