High reputation High Chrome Horizontal Pump - Horizontal Rubber Lined Slurry Pump SHR/200F – Minerals

High reputation High Chrome Horizontal Pump - Horizontal Rubber Lined Slurry Pump SHR/200F – Minerals Detail:

Pump Model: SHR/200F (10/8F-AHR)

SHR/200F is equivalent to 10/8F-AHR, a 8” discharge rubber lined slurry pump, which is widely used for corrosive slurry applications. SHR/200F is horizontal centrifugal type heavy duty rubber lined slurry pump. It is used to handle tailings in various mining sectors. Plus, it can also be used to feed cyclones for sand washing plants, quarries, etc. SHR is high corrosion-resistant pump series for the hydraulic conveyance of liquids-solids of any type. It’s wet-end spare parts are made of natural rubber R55, a black soft natural rubber, which has superior erosion resistance to all other materials in fine particle slurry applications. The high erosion resistance of R55 is provided by the combination of its high resilience, high tensile strength and low Shore Hardness.

Applications:

Mine Dewatering; Sand Pumping; Manure Slurry; Oil Sands; Tailings and Aggregate; Coal Production etc.

Material Construction:

| Part Description | Standard | Alternative |

| Impeller | R55 | Polyurethane |

| Cover Plate Liner |

R55 | Polyurethane |

| Frame Plate Liner |

R55 | Polyurethane |

| Throatbush | R55 | Polyurethane |

| Split Outter Casings | Grey Iron | Ductile Iron |

| Shaft | Carbon Steel | SS304, SS316 |

| Shaft Sleeve | SS304 | SS316, Ceramic, Tungstan Carbide |

| Shaft Seal | Expeller Seal | Gland Packing, Mechanical Seal |

| Bearings | ZWZ, HRB | SKF, Timken, NSK etc. |

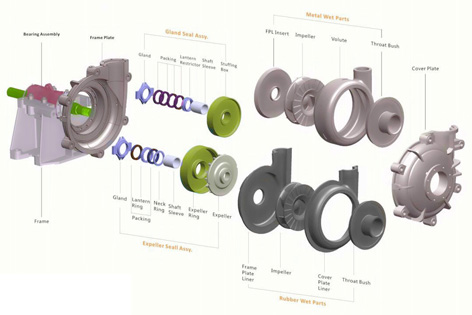

Construction & Structure:

Specifications:

Flowrate: 540-1188m3/hr; Head: 12-50m; Speed: 400-750rpm; Bearing Assembly: FAM005M

(Optional Bearing Assembly: SH005M with Max. Motor Power of 560Kw)

Impeller: 5-Vane Closed Type with Vane Diameter: 686mm; Max. Passage Size: 76mm; Max. Efficiency: 75%

Product detail pictures:

Related Product Guide:

Slurry Pump Knowledge

To consistently enhance the management method by virtue of the rule of "sincerely, fantastic religion and top quality are the base of business development", we extensively absorb the essence of associated goods internationally, and constantly acquire new merchandise to satisfy the needs of shoppers for High reputation High Chrome Horizontal Pump - Horizontal Rubber Lined Slurry Pump SHR/200F – Minerals , The product will supply to all over the world, such as: Philadelphia , United Kingdom , Ecuador , Immediate and specialist after-sale service supplied by our consultant group has happy our buyers. Detailed Info and parameters from the merchandise will probably be sent to you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Morocco for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!