Quality Inspection for Pump Casing - Horizontal Rubber Lined Slurry Pump SHR/200F – Minerals

Quality Inspection for Pump Casing - Horizontal Rubber Lined Slurry Pump SHR/200F – Minerals Detail:

Pump Model: SHR/200F (10/8F-AHR)

SHR/200F is equivalent to 10/8F-AHR, a 8” discharge rubber lined slurry pump, which is widely used for corrosive slurry applications. SHR/200F is horizontal centrifugal type heavy duty rubber lined slurry pump. It is used to handle tailings in various mining sectors. Plus, it can also be used to feed cyclones for sand washing plants, quarries, etc. SHR is high corrosion-resistant pump series for the hydraulic conveyance of liquids-solids of any type. It’s wet-end spare parts are made of natural rubber R55, a black soft natural rubber, which has superior erosion resistance to all other materials in fine particle slurry applications. The high erosion resistance of R55 is provided by the combination of its high resilience, high tensile strength and low Shore Hardness.

Applications:

Mine Dewatering; Sand Pumping; Manure Slurry; Oil Sands; Tailings and Aggregate; Coal Production etc.

Material Construction:

| Part Description | Standard | Alternative |

| Impeller | R55 | Polyurethane |

| Cover Plate Liner |

R55 | Polyurethane |

| Frame Plate Liner |

R55 | Polyurethane |

| Throatbush | R55 | Polyurethane |

| Split Outter Casings | Grey Iron | Ductile Iron |

| Shaft | Carbon Steel | SS304, SS316 |

| Shaft Sleeve | SS304 | SS316, Ceramic, Tungstan Carbide |

| Shaft Seal | Expeller Seal | Gland Packing, Mechanical Seal |

| Bearings | ZWZ, HRB | SKF, Timken, NSK etc. |

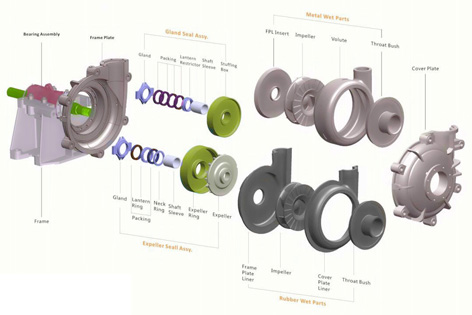

Construction & Structure:

Specifications:

Flowrate: 540-1188m3/hr; Head: 12-50m; Speed: 400-750rpm; Bearing Assembly: FAM005M

(Optional Bearing Assembly: SH005M with Max. Motor Power of 560Kw)

Impeller: 5-Vane Closed Type with Vane Diameter: 686mm; Max. Passage Size: 76mm; Max. Efficiency: 75%

Product detail pictures:

Related Product Guide:

Slurry Pump Knowledge

With the "Client-Oriented" business philosophy, a rigorous quality control system, advanced manufacturing equipment and a strong R&D team, we always provide high quality products, excellent services and competitive prices for Quality Inspection for Pump Casing - Horizontal Rubber Lined Slurry Pump SHR/200F – Minerals , The product will supply to all over the world, such as: Swedish , Curacao , Frankfurt , Make sure you genuinely feel free to send us your requirements and we are going to respond for you asap. We now have got a skilled engineering group to serve for your just about every detailed needs. Cost-free samples could be sent to suit your needs personally to understand much more information. In an effort to meet your requires, be sure to seriously feel free to make contact with us. You may send us emails and contact us directly. Moreover, we welcome visits to our factory from around the globe for much better recognizing of our organization. nd objects. In our trade with merchants of numerous countries, we usually adhere for the principle of equality and mutual benefit. It is really our hope to market, by joint efforts, each trade and friendship to our mutual advantage. We look forward to getting your inquiries.

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!